Komori-Chambon history

Komori-Chambon S.A.S is the result of a long historical line,

initiated in 1887 by Louis Chambon,

then revisited with the Japanese group Komori in 1989.

Komori-Chambon S.A.S is the result of a long historical line,

initiated in 1887 by Louis Chambon,

then revisited with the Japanese group Komori in 1989.

MACHINES CHAMBON

Mr. Louis CHAMBON was born on August 21, 1861 in La Voulte-sur-Rhône. In 1881, he graduated as a mechanical engineer from the Ecole des Arts et Métiers in Aix en Provence, France. Then he moves to Paris, with two employees in a rented workshop. He designs his first machine, a printing press, for a cigarette manufacturer.

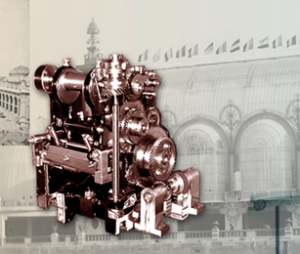

He takes advantage of the opportunity offered by the Paris World Fair to exhibit 5 printing machines. This exhibition brings him commercial success and his first contacts with the sugar industry.

He builds the world’s first webfed printing machine, in 5 colours.

In 1894, the small size of his workshop leads him to acquire a 2800m2 plot of land to build a factory.

Due to the First World War and the cramped premises in Paris, production is transferred to the home town of the company founder in La Voulte- sur-Rhône where the new factory is built.

Death of Louis CHAMBON.

A new chapter of the company’s history is to be written.

MACHINES CHAMBON is established in Orléans La Source, the Paris premises being too small.

KOMORI

In Japan, in 1923, the company KOMORI is created. Since then, KOMORI has grown to become one of the leading manufacturers of OFFSET rotary presses.

KOMORI-CHAMBON

MACHINES CHAMBON integrates the Japanese group KOMORI. From this purchase was born KOMORI-CHAMBON SA.

1st connected PLC.

2nd PLC generation (Komori technology).

1st supervisory computer.

Revolutionary web control system

on a rotary die-cutter : DRX.

1st machine equipped with electrical

shaft/direct drive (Japan).

Automatic printing cassette switch device (USA).

1st connected machine – Ethernet (USA).

1st Offset sleeve press

1st roll-type die-cutter bench

1st delivery solution with independent lifts

tobacco line (Shanghai).

Inspection camera for abhesive, through the web (roll-to-roll application).

Record speed in converting and delivery.

Liquid packaging = 450 m/mn.

New building hosting a demo center KCube (Competence center) and a proto test area.

New generation gravure machine (MARK III Series)

Record printing speed in rotogravure : 500 m/mn (1640 ft/mn) in roll-to-roll – 350 m/mn (1150 ft/mn) in tobacco blanks

Komori celebrates its 100th anniversary

New Generation Presses,

AKCademy kick-off for events, trainings and demo

Komori-Chambon is expanding and opened a new subsidiary in USA

Komori Corporation announces a Business acquisition

to be undertaken by Komori Chambon S.A.S.

Komori-Chambon USA Corporation is born